–

The shortage in the supply of semiconductors for global vehicles has begun to hurt Korean automobile production in earnest. After GM Korea lowered the utilization rate of its Bupyeong 2 plant to 50%, Hyundai Motor Company and Kia are also reducing their extra work (weekend work). It is known that the company is considering temporarily suspending the operation of the plant. There are also concerns that the shortage of semiconductor supply will cause a disruption in the production of next-generation electric vehicles such as Ioniq 5.

○“Tucson and Sorento are also at stake”

According to the automobile industry on the 28th, Hyundai Motor Company has not yet confirmed the schedule for extra work in March for some factories (Ulsan Plant 3, Plant 5, etc.). The company explained to the union that it would set a weekly extra work schedule for the time being. This means that it is difficult to determine the one-month extra work schedule in advance due to uncertainty about the timely supply of semiconductors for vehicles. Previously, the schedule was set in units of one month at the beginning of each month.

The company is also reported to have informed the union that some production lines could be temporarily suspended in the future. Popular models such as Avante, Tucson, and Kona were also included in the review target. In March, Kia decided to eliminate the overtime at the Hwaseong plant. Production disruptions such as Kia’s representative sports utility vehicle (SUV) Sorento became inevitable.

–

–

Hyundai Motor Company and Kia have recently been negotiating directly with semiconductor manufacturers regarding supply. Previously, parts containing semiconductors were supplied from primary suppliers such as Hyundai Mobis Bosch, but it is explained that it has made direct contact with semiconductor companies to prevent the worst situation in which the production line is stopped due to a shortage of semiconductors.

First, GM Korea, which started to cut production, decided to cut production by mid-March. GM Korea has cut the utilization rate of its Bupyeong 2 plant in half since early February when some of the semiconductors supplied by General Motors (GM), the headquarters of the United States, became scarce. Bupyeong Plant 2 produces Malibu and Trax.

○ Tesla was also hit by a shortage of semiconductors

The disruption in automobile production due to shortage of semiconductors is spreading around the world. Most global automakers, such as Toyota, Volkswagen, Ford, Renault, and Nissan, have recently shut down their factories or reduced their utilization rates due to lack of semiconductors.

Tesla, an electric vehicle maker in the US, was also unable to avoid the semiconductor supply shortage. Bloomberg reported, citing sources, that Tesla has notified workers on the Model 3 assembly line at its Fremont, California plant, of the suspension of production. It is reported that the discontinuation of Model 3 production at the Fremont plant will continue until the 7th if it began on the 22nd.

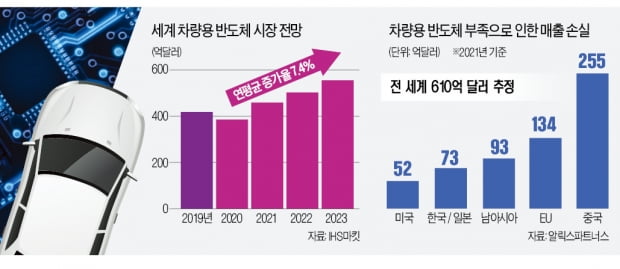

Market research firm IHS Markit reported that the global automobile production volume of automobiles in the first quarter of this year will decrease by about 1 million units due to the semiconductor supply shortage. Global consulting firm Alix Partners forecasts that the total sales of global automakers will decrease by $61 billion (about 70 trillion won).

The shortage of automotive semiconductor supplies began last year. Global automakers predicted that car sales would drop sharply due to the Corona 19 pandemic, and they drastically reduced semiconductor orders. Meanwhile, foundry (consigned semiconductor production) companies focused on the production of semiconductors related to home appliances and information technology (IT).

However, global automobile sales rebounded in the second half of last year, and automakers belatedly increased their semiconductor orders. However, foundry companies that have already received orders for several months from home appliance companies do not have enough production capacity.

Some of the industry is concerned about disruptions in production of next-generation electric vehicles such as Hyundai Motor Company Ioniq 5. Internal combustion locomotives contain 200 to 400 semiconductors, and electric vehicles are known to require 100 more semiconductors.

Experts predict that automotive semiconductor shortages will continue until at least the third quarter of this year. This is because even if an order is placed at a semiconductor company right away, it takes about 6 months to produce. It is virtually difficult to secure new suppliers because automakers seldom leave production of semiconductors for vehicles to new companies for stability reasons.

Reporter Do Byeong-wook [email protected]

–