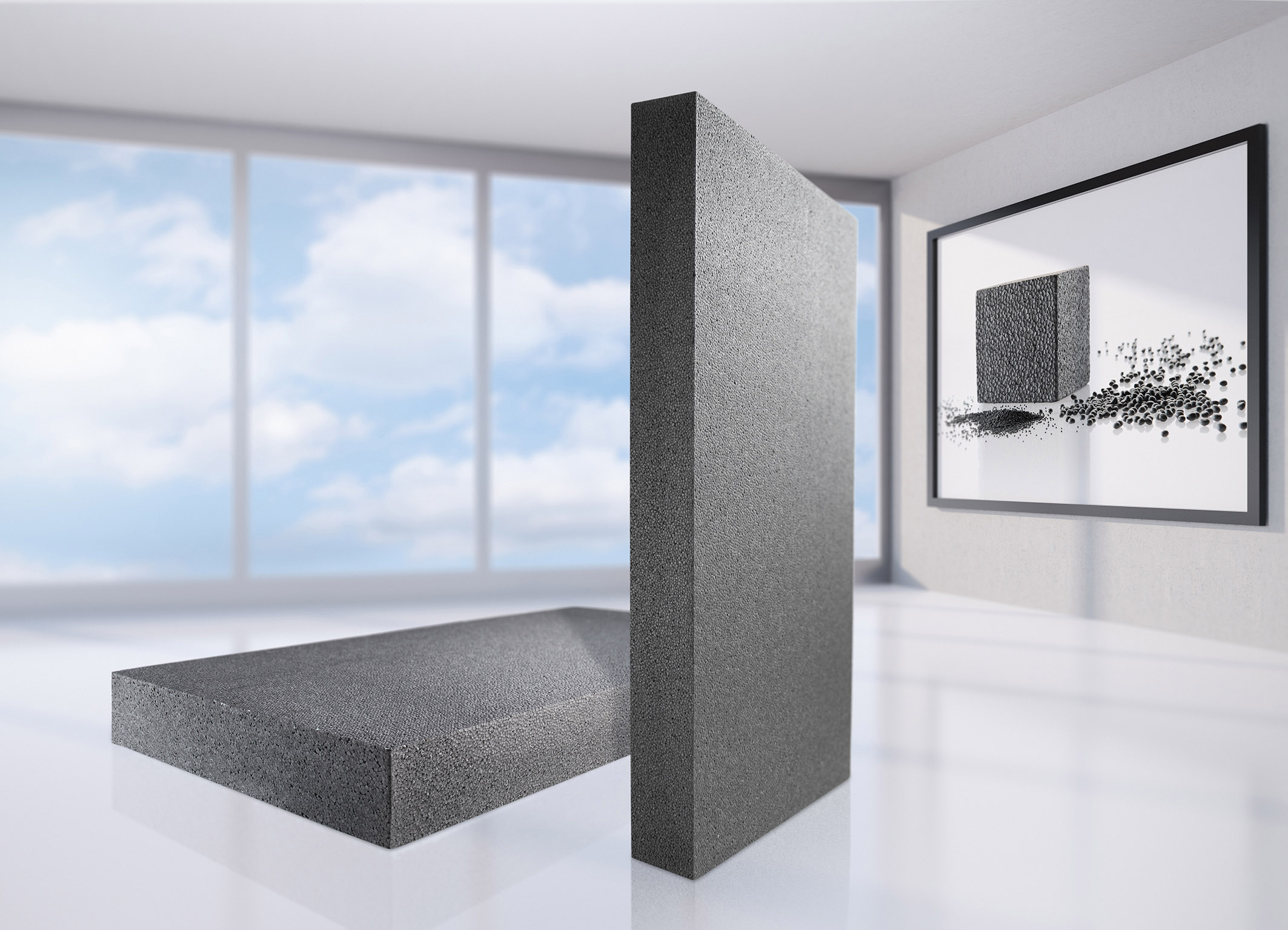

BASF, Ludwigshafen, expands its portfolio for expandable polystyrene granulate (EPS) containing graphite. Neopor F 5 Mcycled contains 10% recycled material and is suitable for numerous applications in buildings, especially for facade insulation.

–

–

Graphithaltiges expandierbares Polystyrol-Granulat (EPS) Neopor F 5 Mcycled. (Image: BASF)

–

–

BASF, Ludwigshafen, together with the company Karl Bachl, Röhrnbach, developed the new raw material and made it ready for the market. The quality of the recyclate used plays a central role in meeting the high product requirements in the various construction applications. Both the recyclate used and the insulating raw material are REDcert2-certified. The recyclate comes from mechanically recycled EPS waste. Insulating materials made from Neopor are now the standard for façade insulation in both new builds and renovations. During their decades of use, they reduce CO2-Emissions of the building significantly. With Neopor F 5 Mcycled, BASF is expanding its EPS portfolio with an improved sustainability profile. The new raw material supplements the mass-balanced products Styropor CcycledTM and Neopor BMB, which are manufactured on the basis of alternative raw materials.

–

–

Energy savings in process heat generation

–

–

–