On Wednesday, December 29 (SOL 306) Perseverance successfully drilled and extracted a sample of Martian rock. The downlink-related data after sampling showed that the rock drilling by the science team named Isol was running smoothly. However, when transferring the sample containing part to the bit rover carousel (which stores the bits and passes the tube to the tube processing device inside the rover), our sensor shows an anomaly. Rover did what it was designed to do – shut down spooling procedures and called home for further instructions.

It’s only 6you Time in human history rock samples were mined on planets other than Earth, so when we see something anomalous happen, we slowly accept it. Here’s what we know so far, and what to do about it.

An anomaly occurred during the Coring Bit Dropoff. This occurs when the drill bit, with the sample tube and sample drilled in it, is directed out of the percussion drill (at the end of the robot arm) and into the drill carousel (located in the plow chassis). When processing a pre-grain rock sample, the drill bit moves 5.15 inches (13.1 cm) before the sensor starts recording the type of drag (pull) expected on first contact with the circular structure. However, this time the sensor recorded a higher-than-usual resistance about 0.4 inches (1 cm) earlier than expected, and some resistance was much higher than expected during operation.

The team requested additional data and images to ensure a proper understanding of the post-anomaly situation. Because we are currently working with a “constrained” cluster where data latency limits the type of activity we can perform on Mars, it will take us about a week to receive the additional diagnostic data needed to understand this anomaly.

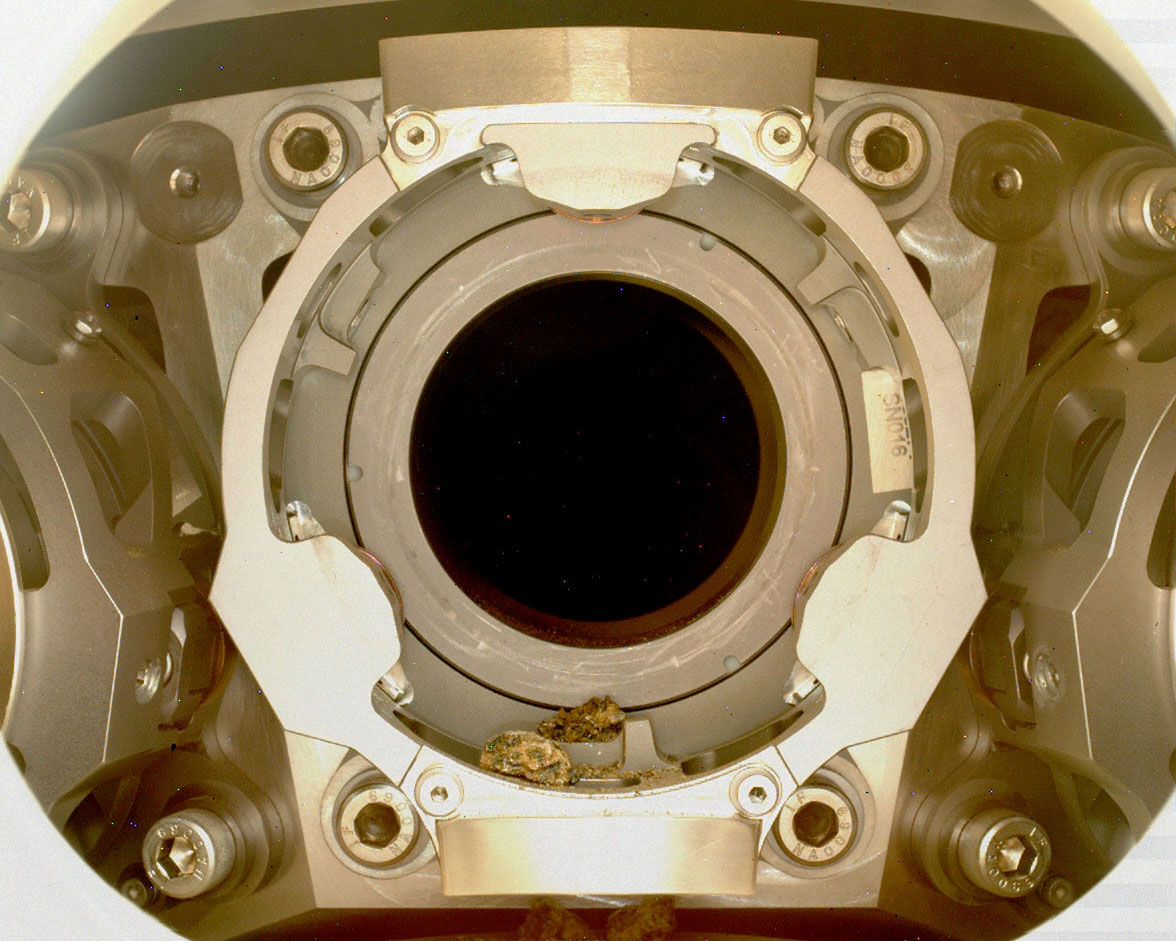

Armed with this dataset, we send commands to extract the drill bit and sample tube from the carousel bit and remove the robot arm from the carousel bit. During this activity, a series of device images was obtained.

The extraction was carried out yesterday (1/6) and the data was transferred this morning. The recent images associated with this downlink confirm the presence of several pieces of gravel-sized debris within the bit circuit. The team believes that these are shards of quarry that fell from the sample tube during the Coring Bit Dropoff, and that they prevented the piece from completely sitting in the bit carousel.

The bit circuit designer took into account the ability to continue to work successfully with debris. However, this was our first time removing debris and we wanted to take the time necessary to ensure that the gravel came out in an orderly and disciplined manner. We will continue to evaluate our data set over the weekend.

This isn’t the first curve Mars has thrown at us – just the most recent. One thing we found was that when engineering challenges are hundreds of millions of miles away (Mars is currently 215 million miles from Earth), you need to take your time and be precise. We’ll do it here. So when we hit the tarmac of Mars again, our sample set of persistence is ready to go.

–