display

The Technical University of Kaiserslautern and the Smart Factory KL technology initiative jointly launched the “5G – Use in Industry” project. The aim is to create a powerful network that can draw on years of theoretical and practical experience.

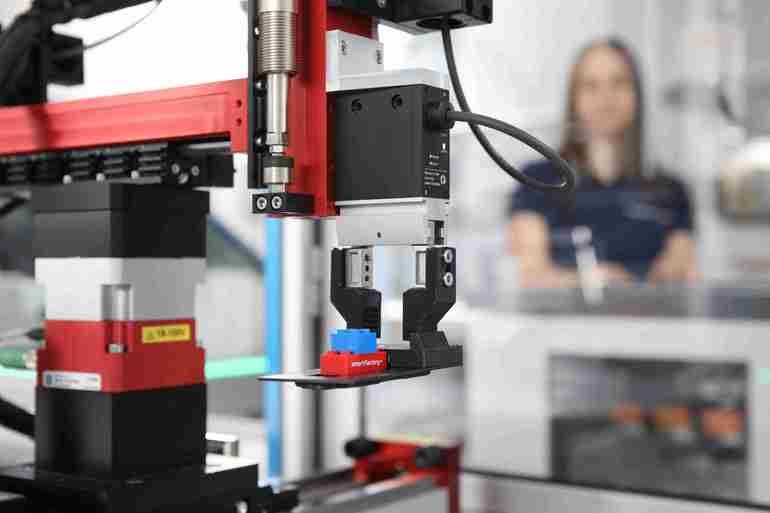

The industry demands flexible production systems, such as those in visionary concepts Industry 4.0 or Production Level 4 are described. In order to achieve changeability in production halls, networked modules that can be dynamically linked or exchanged are essential, as the technology initiative Smart Factory KL explains. The properties of the 5G mobile radio standard are ideal for meeting these high requirements in terms of latency, data throughput and reliability.

Why wireless communication?

Modular production systems offer flexible manufacturing. Module replacement is a core feature of the visionary concepts of the factory of the future. Communication via cable is the opposite of an adaptable network. Here funk is indispensable. As a requirement it is formulated that the radio network works reliably even in adverse factory environments.

5G as a door opener for augmented reality

Prof. Hans Schotten, chair holder of radio communication and navigation at DFKI explains: “We know numerous mobile applications from the consumer sector that also have great potential in industry, for example augmented reality or wireless control and monitoring devices. In industry, these can be safety-critical – an emergency stop via radio, for example. That is only possible with a powerful and reliable radio technology like 5G. Augmented Reality (AR) can support use cases such as commissioning, maintenance and assembly of complex machines in the industrial sector. So far, the potential has not been fully exploited due to the poor performance of existing tracking software solutions in dynamic environments. In addition, existing cellular network infrastructures fail due to the bandwidth and latency requirements of AR processes. Here, too, 5G could offer a solution. “

High tech from Rhineland-Palatinate

The aim of the project is to enable the University of Kaiserslautern, essentially as a technologically savvy pioneer in the field of Industry 4.0 and intelligent networks, to expand the fundamental basis with regard to 5G. The implementation of a 5G infrastructure will play a decisive role in the development of competencies and the adequate execution of tests for practical testing of the suitability of 5G technology. According to Smart Factory KL, the experience with 5G and the transfer to applied research will help to address the challenges facing industry, especially medium-sized companies. Specific requirements with regard to changeable and dynamic system concepts, new functionalities and the development of new business fields can be tested and addressed in a practical manner.

Rhineland-Palatinate will benefit from the particular agility and the existing knowledge in the field of Industry 4.0 and industrial communication, it is said. In the medium and long term, know-how and best practices can be accumulated in order to demonstrate technical feasibility and to motivate companies to use aspects of 5G and the resulting technological achievements with considerable added value in existing and future systems.

The research project is supported by ERDF and state funds from the Ministry of Economic Affairs with around 830,000 euros.

What is Production Level 4?

The term Production Level 4 describes the level of autonomous production that the Smart Factory KL technology initiative sees as desirable and currently possible. In this context, people, as decision-makers and those responsible, are the focus of production. Level 4 was therefore chosen deliberately, since level 5, the highest level of the level of autonomous driving, already excludes people. However, according to the initiative, this exclusion does not appear to be either expedient or feasible.

For Smart Factory KL, Production Level 4 is a further development within the era of Industry 4.0. While Industry 4.0 offers the rough framework for digitization and the networking of machines, Production Level 4 integrates autonomy, people and IT as autonomous elements. These communicate with each other and enable maximum agility within production for products of batch size 1.

More here: www.smartfactory.de/production-level-4

Via the technology initiative Smart Factory KL eV

Smart Factory KL describes a research and industry network that rests on three pillars, an association and two scientific institutions. Research institutes and industrial companies are members of the technology initiative SmartFactory KL eV. The association stands for questions related to industrial production, which are answered in the scientific research institutions “Innovative Factory Systems” at the DFKI and at the Chair “Machine Tools and Controls” (WSKL) at the Technical University of Kaiserslautern. Prof. Martin Ruskowski has been an organizational and content-related bracket since 2019. He is chairman of the board of the association, head of the DFKI research area and holder of the chair. The association brings together stakeholders from industry and science in an Industry 4.0 network in order to jointly develop and implement projects for the factory of the future. On this manufacturer-independent demonstration and research platform, scientists and industry representatives test innovative production technologies in a realistic factory environment. In 2016 the Federal Ministry for Economic Affairs and Energy appointed the Smart Factory KL as the consortium leader of the Mittelstand 4.0 – Competence Center Kaiserslautern. In 2019, the network revised the concept of Industry 4.0 and named the update Production Level 4 (PL4). In 2020, the Smart Factory KL presented what it claims to be the world’s first PL4 demonstrator, which is to be continuously developed in the direction of autonomous production in the coming years. The association has been involved in the European Gaia-X network with the smartMA-X research project since 2020. The PL4 demonstrator plays a central role in this. The technology initiative is also one of the founding members of the SmartFactory-EU.

Contact:

Technology Initiative SmartFactory KL eV

Trippstadter Strasse 122

67663 Kaiserslautern

www.smartfactory.de

–