–

Schindler Vocational Training starts the new year in an innovative way. More precisely, with the commissioning of a metal 3D printer.

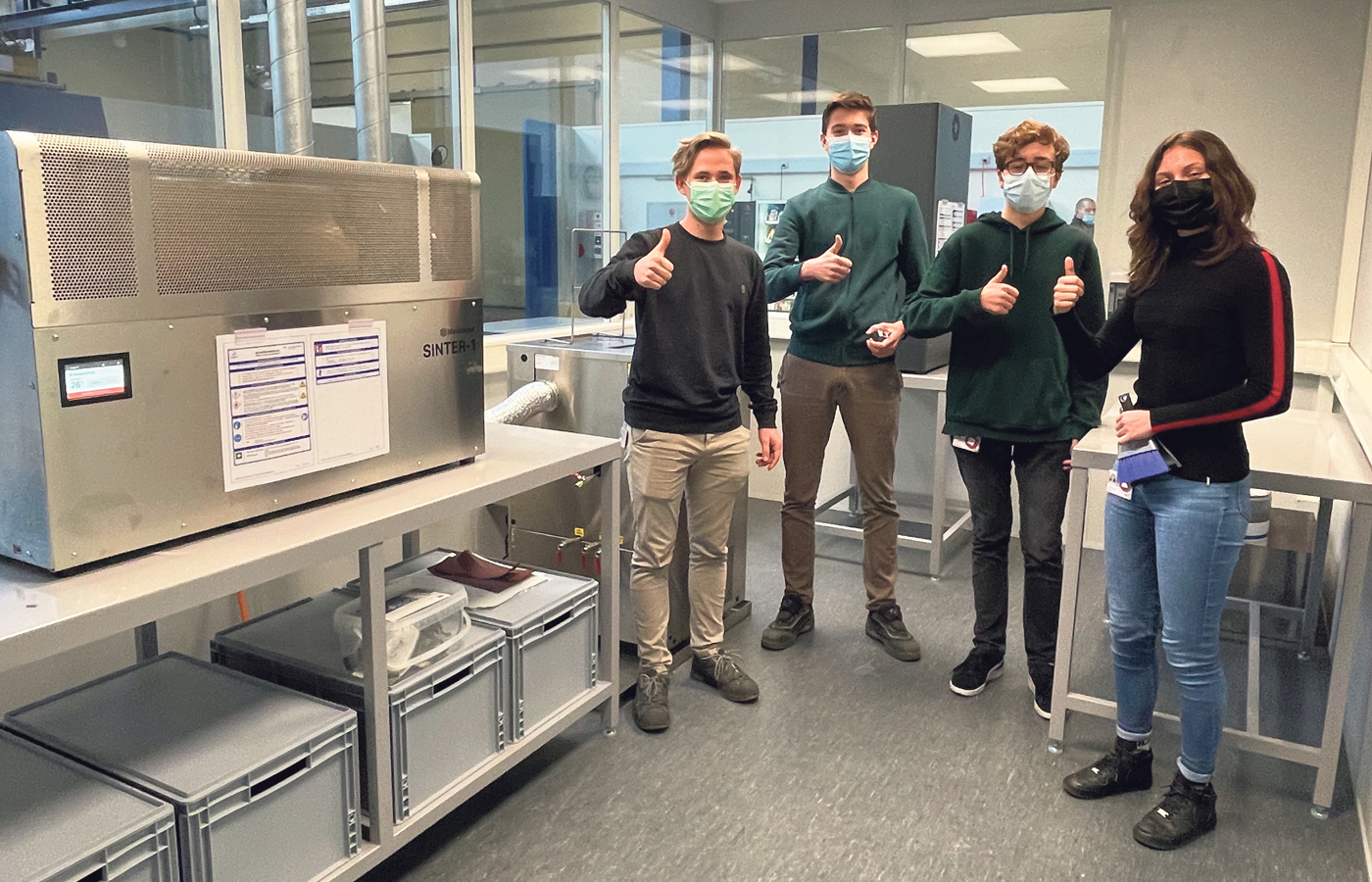

Schindler Vocational Training and the in-house innovation department “New Technology” made a new acquisition – a metal 3D printer with an associated cleaning bath and furnace. The new devices made many demands on the structural environment. Now it’s done and we can use the devices safely. Now we would like to make this new technology accessible to all employees and thus gain new experience.

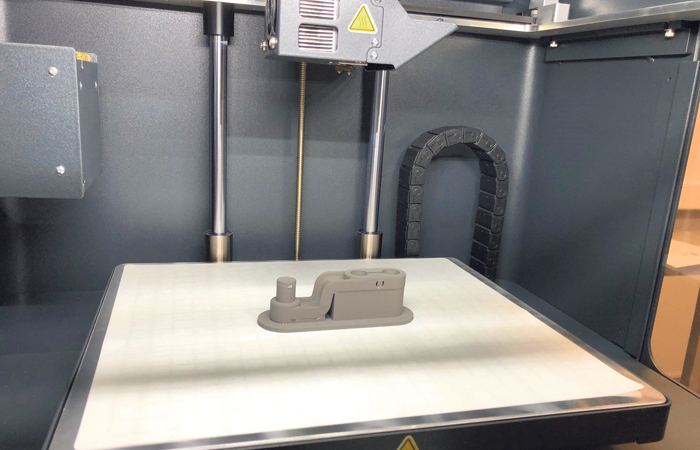

The innovative manufacturing process offers new possibilities in component design. The pieces to be produced can have complex shapes or cavities which cannot be produced by conventional machines. Now our budding designers are faced with a double challenge. You have to think about when this new manufacturing process makes sense and when to use conventional manufacturing.

Manufacturing process

The desired component is drawn by our design engineers in training and is then produced in the 3D printer. After printing, the component is cleaned in a special liquid and is finally placed in an oven for 27 hours (called a sintering oven in technical terms). This last step is absolutely necessary because at around 1200 degrees Celsius the component shrinks by 20%. It is then consolidated and can be installed.

We also print your order.

Ask us today – we will be happy to advise you.

Your construction department of Schindler vocational training

Telephone 041 445 34 77