The IRT SystemX innovates in the field of mechanical system design by reducing models and multi-physics optimization with the DCIDE software platform (Dashboard for Collaborative Innovative DEcision) and the ReCUR calculation module (Regression CUR), developed with the support of Renault Group and ESI Group.

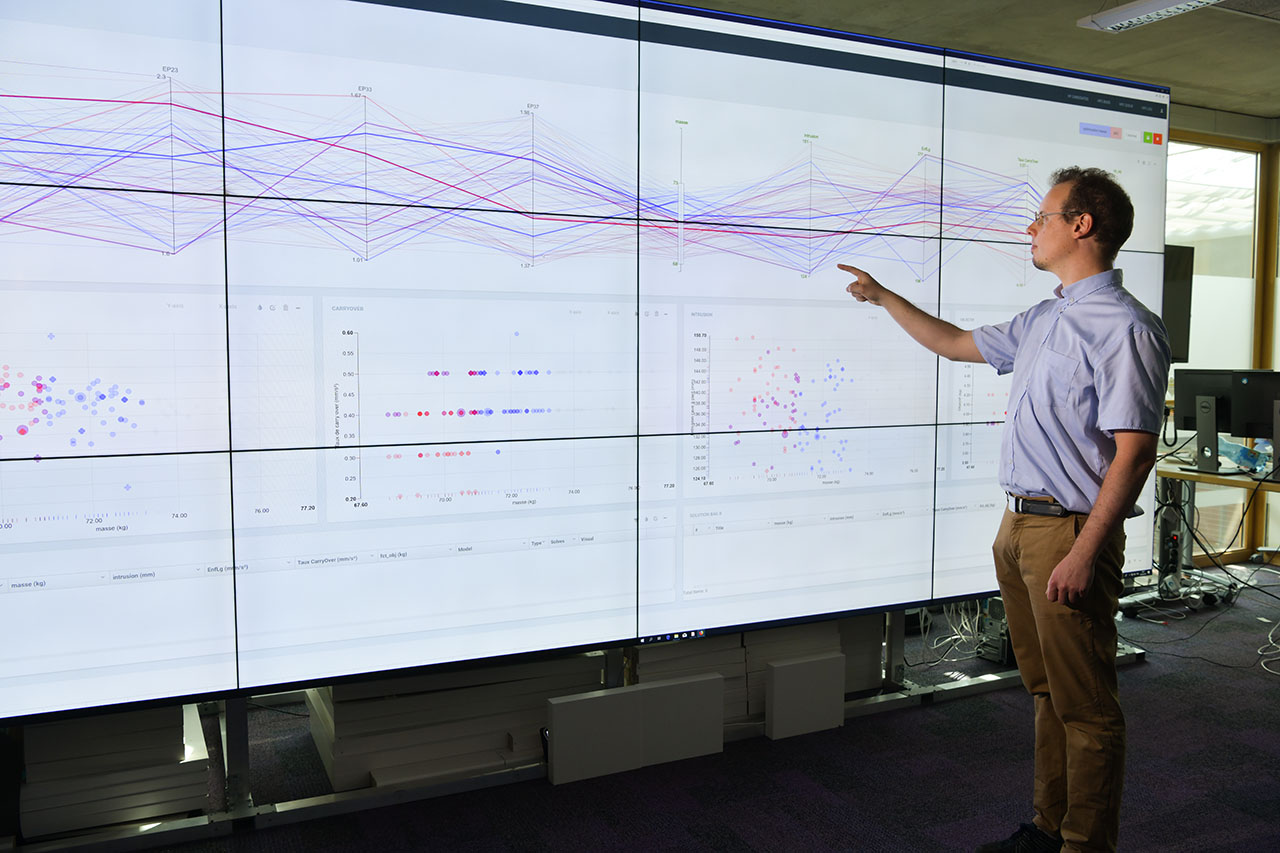

These complementary technological bricks support mechanical system design teams by giving them access to an interactive, collaborative and decentralized Human-Machine Interface for viewing results and controlling computing infrastructures (DCIDE), and by offering them methods of reduction of innovative models (ReCUR). The combination of DCIDE and ReCUR makes it possible to drastically reduce the computation times, while maintaining an exhaustive representativeness of the simulation results. “This solution was used by Re-nault to find, in a few iterations of calculation, the optimization of the body model of the Renault Talisman, instead of several months of study. », Jean-Patrick Brunet, Software & DevOps Architect, IRT SystemX. An extension of DCIDE’s work within the AMC and I (SC) 2 projects The Agility of Design Margins (AMC) project of IRT SystemX used DCIDE to accelerate the development of its SimArt (Simulation Architect Tool) platform . Its ambition: to strengthen collaboration between all the players in the complex system design chain by means of tools connected to the computing infrastructures and thus guarantee an optimal search for efficient solutions. The Collaborative System Engineering of Complex Systems (I (SC) ²) project completes this collaborative platform by offering new decision-making support functions in terms of system architecture choices: visualization of preference models for evaluation and choice of architecture, functionality for comparing architectures scores, visualization of the uncertainty of the parameters involved.

–