In a tutored project, two students from the IUT GMP prototyped an innovative system capable of producing electricity from the movement of sailboats at anchor. Guind’Elec would cover 30% of daily needs.

–

It was during his previous summer vacation that the idea came to him. The night spent at anchor, Tom David noticed that the energy voracity of the on-board electrical devices got the better of the service batteries of his sailboat. Thoughtful, he observes the coming and going of other ships on the near horizon under the effect of the swell, waves and wind, the tension and the loosening of the anchor chains …

“I said to myself that it was a shame to lose this energy, that there had to be a way to recover it and use it to supply the auxiliary batteries”, explains Tom David.

Current ecological systems are not enough to power ships overnight. They must then be replaced by an alternator connected to the engine of the boat, a fuel cell or a generator, all three users of thermal energy.

“The goal is not to supplant solar panels or wind turbines but to offer a complementary system that would allow ships to be self-sufficient in electricity, not to break down due to the consumption of electrical devices and to oblige boaters to restart the engine to recharge the batteries. “

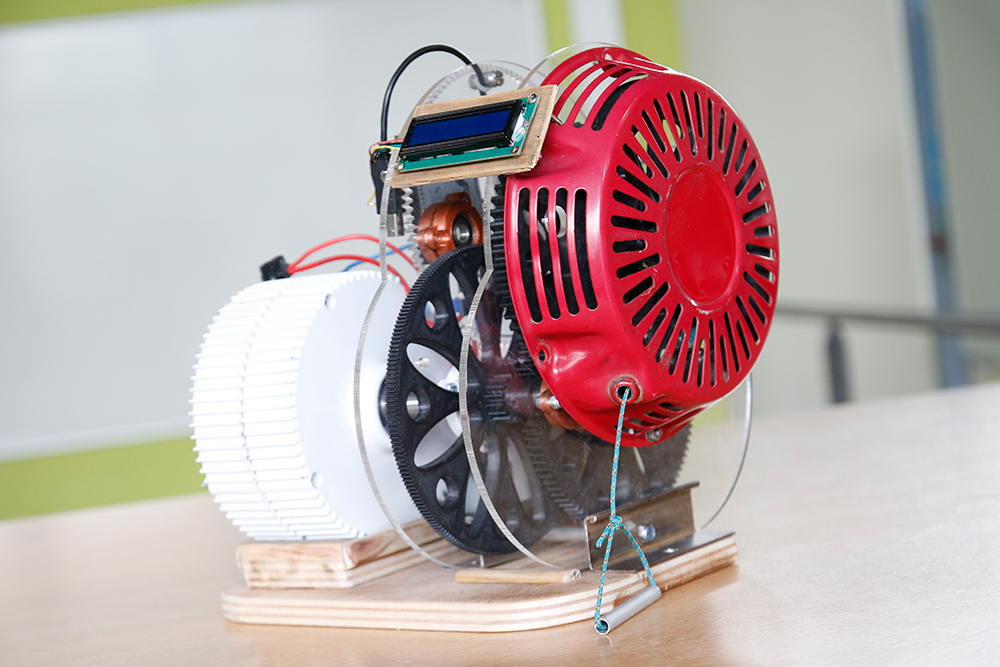

It will take three months for Tom David to imagine a sufficiently powerful device. Its first idea – a spring and a lever arm connected to an alternator – failed on the amplitude generated by its movement, insufficient to produce electricity. It was finally by being inspired by the launchers of agricultural machinery that the young man had the idea of fixing a winding pulley in parallel with the chain of the anchor, which would tighten and relax with the movement of the sailboat. Its integrated spiral spring would rewind the cable with each effort and transform it into electricity by the drive effect of the alternator.

A project developed in the GMP workshops

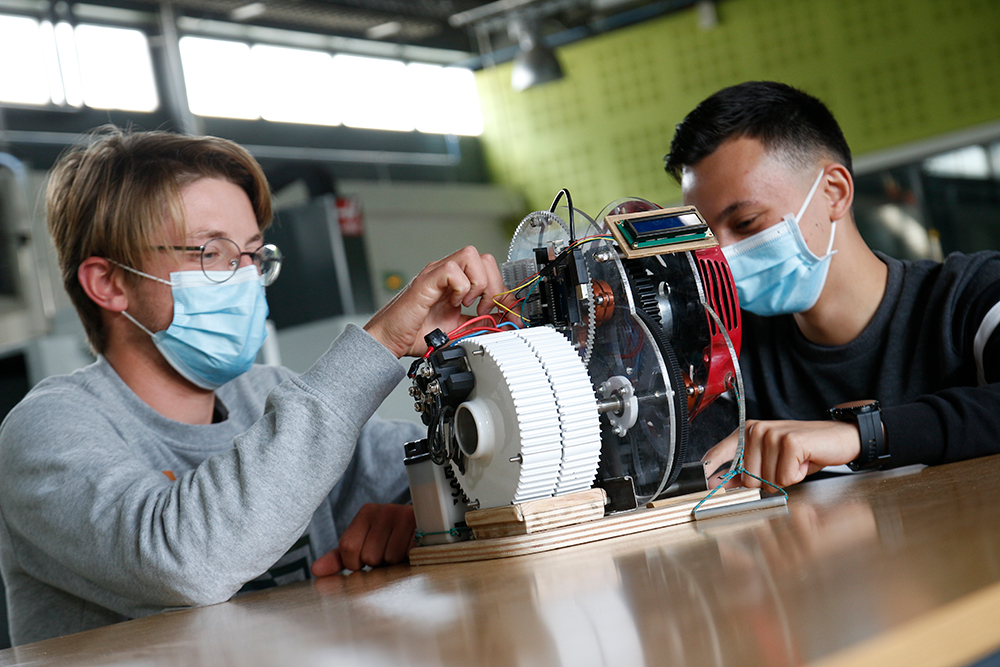

By integrating the Mechanical and Productive Engineering (GMP) department of the IUT of Toulon, Tom was able to propose and develop his idea in a tutored project. A synthesis activity to apply the methods of analysis, collective organization, meeting management taught on concrete industrial cases.

Nicolas Passe, as well as Nicolas Rivière, Thomas Slack and Mathis Neu Feuillère, will accompany him. The group will take nearly a year and a half, interspersed with confinements, to give shape to this green electricity production system.

“Quickly, we made the strategic choice to create a website to keep the link between us and with our tutor, describes Nicolas Passe. It includes meeting reports, planning, provisional planning, functional and provisional specifications. “

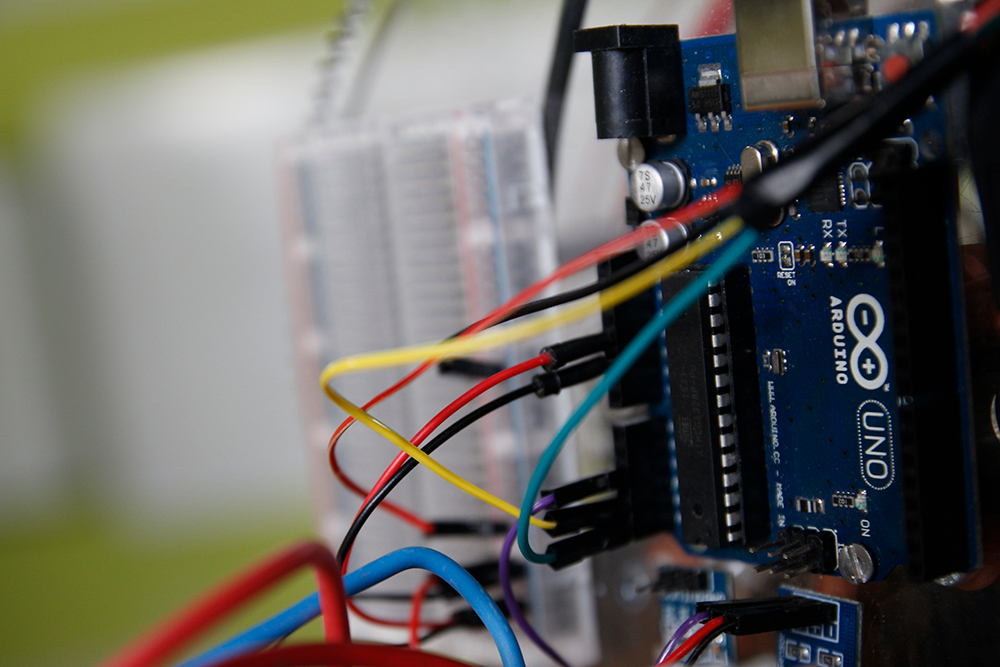

During their first semester, the group went through a first stage of computer-aided design (CAD) of the multiplier: energy transformation, sizing study and calculations, total system dimensions, force calculation, modeling and positioning of the axes. . Nothing was left to chance before making, in the second semester, a first plexiglass model in the workshops of the GMP department, on the La Garde campus.

A second model designed in 3D printing allowed them to carry out initial feasibility tests and obtain results close to reality before making a Guind’Élec prototype. Adaptable to all sailboats, it would cover 30% of daily needs.

Optimization (the gears have honeycomb shapes inspired by watches to gain weight and speed of manufacture without loss of performance) or production of parts, the students wished to develop a “general public” system.

All that remains is to pass the last tests with flying colors, in real conditions.

–