Tesla Battery Day has just come to an end and the company has announced impressive performance and planned changes. Tesla is proving once again that they are setting the tone for a sustainable future, not just for the car industry.

The biggest message at the event was that “Tera” is the new “Giga” (kilo = 1’000, mega = 1’000 kilo, giga = 1’000 mega, tera = 1’000 giga). Achieving a future in which all vehicles are zero-emission requires an increase in the production of batteries and a reduction in their price.

Tesla, founded in 2003. and delivered its first vehicle only 12 years ago, is now setting the tone for the auto industry and beyond. But car manufacturing is not the only thing Tesla does. Ilon Mask, Tesla’s CEO, has repeatedly recalled that Tesla is also a manufacturer of software, batteries, solar panels and many different complex systems with a view to a sustainable future.

New batteries will be significantly cheaper

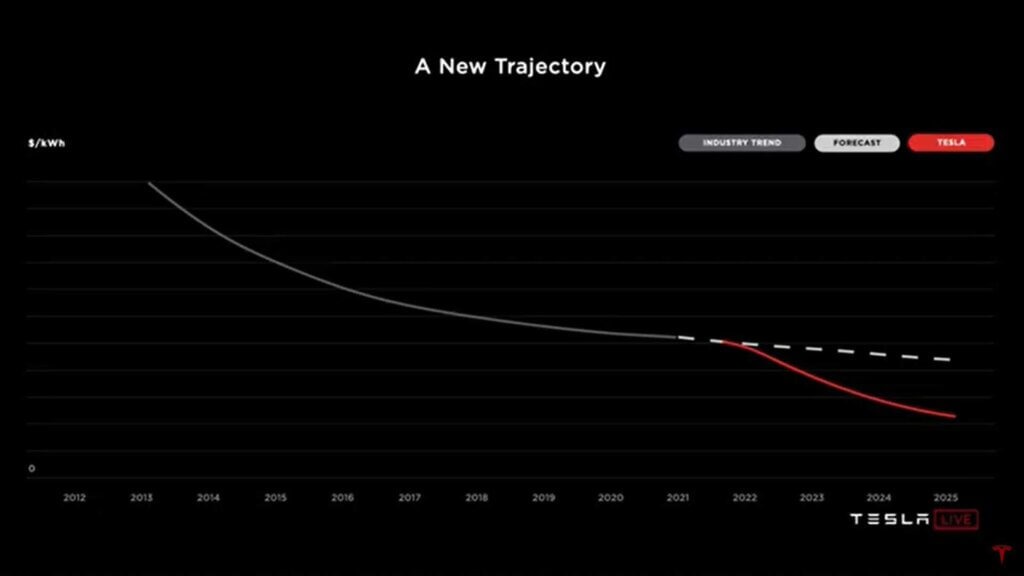

Currently, the main barrier to the adoption of mass electric cars and energy storage systems is the price of batteries (and production capacity). Although battery prices over the past 10 years have been dropped very significantlyIn recent years, this has not happened so fast. Ilon even said they were stagnant. That’s why Tesla has come up with a solution that will reduce the price of batteries by more than 50% in the coming years.

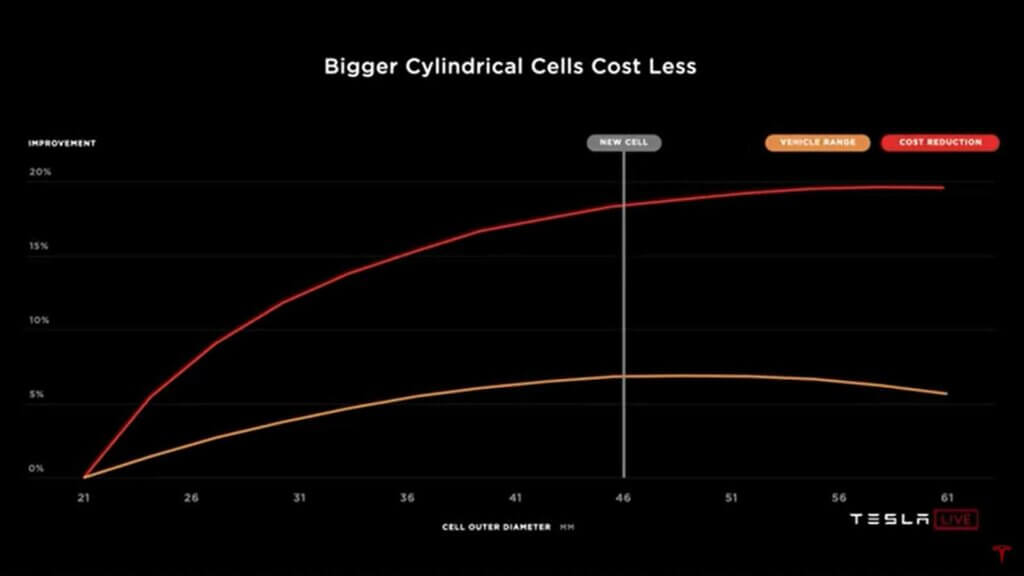

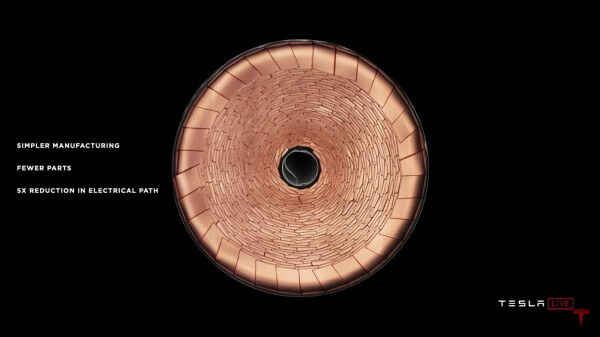

This will be achieved through a complex set of processes. The first of the influencing factors presented is the battery cells themselves. Tesla will develop a new battery shape factor. If so far Tesla used cylindrical battery cells with a shape of 1865 (18 mm in diameter and 65 mm in height) and 2170, then the new batteries will be 4680 and with many internal changes. Previously, the disadvantage of thicker batteries was heating, but Tesla solved this by moving the anode to another location and other processes.

The new form factor enables 5x more power capacity, 6x more power capacity and 16% mileage gain compared to previous batteries, taking up the same amount of space. Using it will achieve 14% price gain.

Tesla will produce the batteries itself

Tesla will start producing battery cells itself (so far its partners). If until now the production process used wet production, which requires significant drying equipment (several hundred meters long), now Tesla will switch to the dry assembly process, which is still in the prototype stage.

The dry assembly process is more efficient and uses significantly cheaper technologies, but is still not fully developed. Compared to wet production, the space required for production is 10x less and the production process is 10x more efficient (consumes less energy). At the same time, Tesla has made putting battery paths together in battery packs more efficient – 7x faster than before.

Over time, all car manufacturers will have an electric car that can travel far. Over time, all cars will be able to drive autonomously. But not all manufacturers will be brilliant in production. Tesla will be head and shoulders superior to the rest. That is our goal.

Ilon Mask, Chairman of the Board, CEO and Product Architect of Tesla Motors

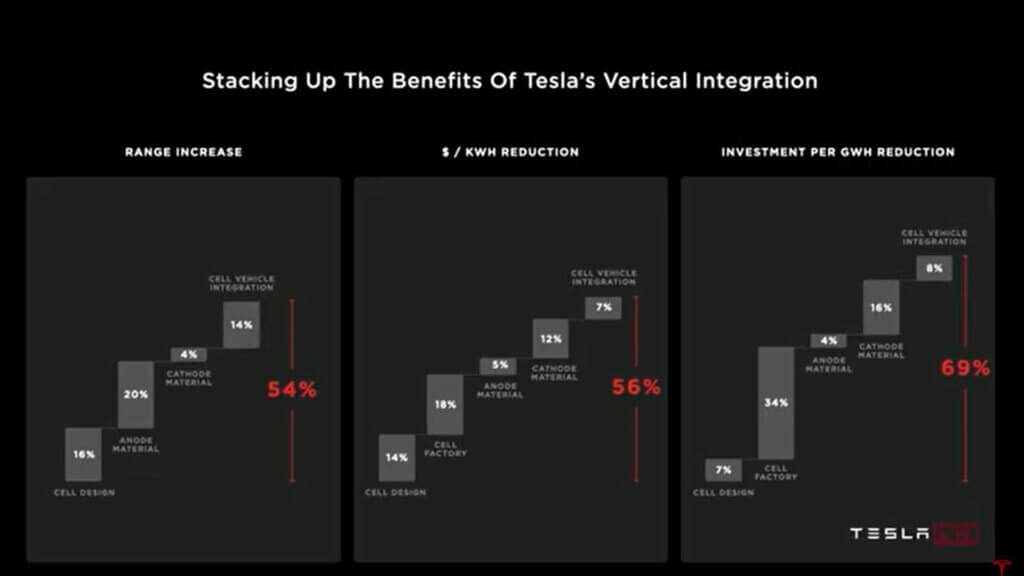

The above is and will be achieved, because Tesla is one of the few companies for which the whole process is vertically integrated. Road production was one of the few processes where the company relied on other manufacturers (Panasonic, Catlus). By managing the whole process, it can be greatly optimized.

Battery production will only increase

Tesla produces few batteries compared to future plans. Until 2022 The California company plans to produce 100 GWh of energy per year, but by 2030. to achieve that 3 TWh / year is produced. If at the expense of Tesla Model 3 units, then in 2030. Tesla will produce enough batteries to fit 40 million Tesla Model 3 Long Range batteries.

With the new production process will be achieved 18% price savings. These two improvements alone will deliver 32% price drop.

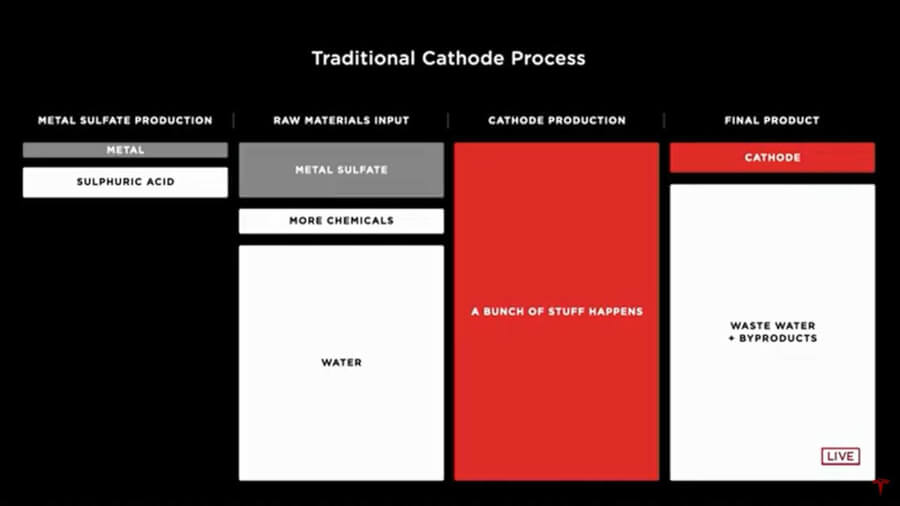

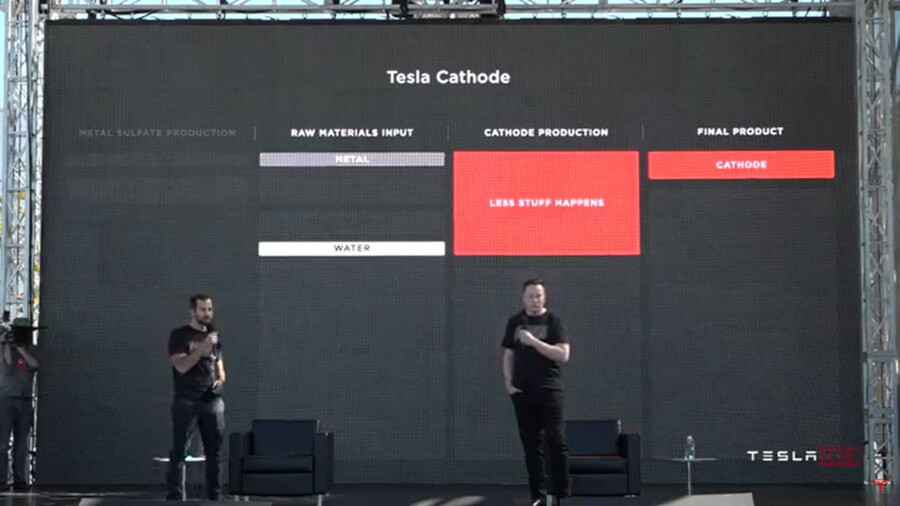

Without cobalt and without excess water

Tesla has long been committed to cobalt-free batteries. They already use the smallest amount of cobalt in their cells when it comes to NCA batteries, but so far have not got rid of it at all for safety reasons.

reduce the price by another 17%. Together already 49% savings.

reduce the price by another 17%. Together already 49% savings.

Batteries will be part of the construction of the machine

The most logical design of electric cars is the “skateboard” design, where the batteries are built into the floor. Tesla will now use battery packs as a floor. The idea comes from the aerospace industry, where the fuel tank used to be in the wing, but now the wing is a fuel tank. This means that the machines will have even fewer parts and there will be more space for the cells.

In this way, more would be achieved 7% savings. Together making battery price 56% lower.

Price is not the only improvement

Improving processes is accompanied by other improvements. Tesla claims that energy capacity has been increased by 54%. This means that the Model 3 Long Range with existing battery capacity would either be able to travel 862 km (560 km (WLTP) + 54%) on a single charge, or the batteries would take up less space, making the machine lighter. Another improvement is the amount of investment required, which Tesla claims is 69% lower.

When will we see it in life?

Ilon said that these improvements will reach real products in 1-3 years. Other carmakers will only present their first electric cars this period…

Another thing

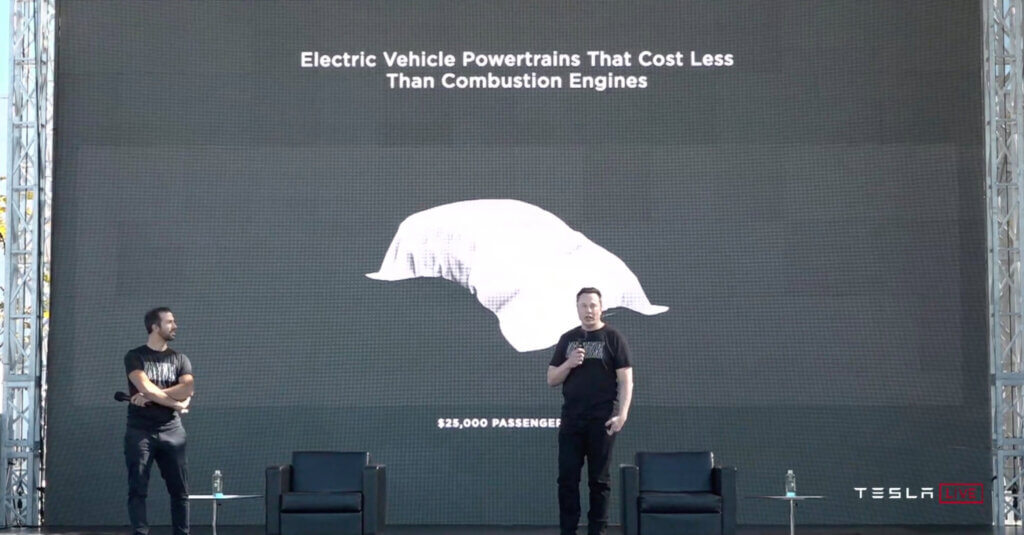

Hints of a new electric car from Tesla appeared several times in the presentation. At the end of the presentation, Ilon shared that there are plans to develop a Tesla car that will cost $ 25,000. Hopefully, the plans for this machine won’t follow a similar path as the $ 35,000 Model 3 or the $ 39,000 Model Y.

In view of the above, it could be expected that this small car will be equipped with a relatively significant battery, which will make other car manufacturers fade.

And one more thing

Recently, some serious competitors for Tesla Model S have appeared. Ilon doesn’t like it when someone able to catch up and not let Die’s yet beat him. The Tesla Model S Plaid was unveiled.

For $ 139’990 you can buy an electric car that is equipped with 3 engines, enables 836+ km on a single charge, is electronically limited to 320 km / h and can run up to 100 km / h in <2.0 seconds. If such figures are for a 5-seater sedan, what will be the figures for the Tesla Roadster 2? Delivery from the end of next year.

The full video of the event can be watched below.

The news is so shocking that today and in the coming months, the rest of the industry is planning a lot of meetings to talk about how to change its strategy. Pat VW MEB platform will hardly be able to compete seriously with this. Especially because the next Tesla plant is being built in Berlin at a rapid pace.