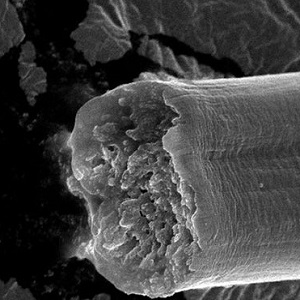

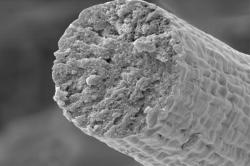

The advantage of spider fibers is their fineness, flexibility and strength (the diameter of the fiber is only 3 to 4 microns) Credit: Yintan, Wikipedia, CC BY 4.0.

–

Fuzhong Zhang is a Chinese working at the McKelvey School of Engineering, a research institute under Washington University (USA). Initially, Zhang worked with spider fibers, but because it is difficult to negotiate with spiders, in 2018 his laboratory created bacteria that managed to produce their proteins as well.

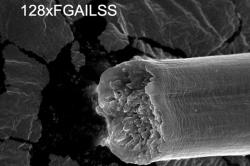

Escherichia Coli bacteria can also make the material from which spider-like fiber can be spun. They are magnified 10,000 × in the electron microscope image. Photo: Eric Erbe, free work.

–

And because recombinant spider silk withstood a comparison to its natural counterpart in all its important mechanical properties, Zhang suddenly became a world-renowned bioengineer. The Lord’s hand with funds for further research opened up to him, and last year alone he received a $ 2 million grant. Today we will look at some of what he has managed to explore in those two years.

One month ago, Zhang’s team reported in the specialized journal ACS Nano about the fusion of amyloid peptides with flexible spidroin linkers and that structural analyzes of the fibers reveal the presence of β-nanocrystals. Translated into human, this means that he learned again from spiders and used spider spidroin to prepare his fibers.

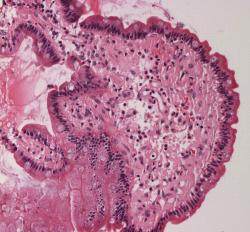

Amyloid is a term for an aggregate of proteins that are characterized by the fact that they can be visualized as “Congo red”. The name itself is a bit unfortunate. It comes from the time when Rudolf Virchow thought from the autopsy findings that it was starch or glycogen (amylon is a Greek term for starch). Amyloids have begun to be associated with neurodegenerative disorders. Over time, it turns out that there will be many more. They currently have 50 human diseases called amyloidosis on their shirt. This is due to the willingness of amyloid monomers to polymerize and their fibrillar character prone to “scratching” – a change in conformational structure (see prion diseases). Credit photomicrograph with pinkish homogeneous amyloid deposits: Michael Feldman, MD, PhD University of Pennsylvania School of Medicine. CC BY 2.0.

–

Spidroin is the main protein that spiders make in their dream glands. It will probably come as a surprise to most of us that it is not that the fluid expelled from the nipples on the spider’s butt solidifies after contact with atmospheric oxygen (as is traditional), but that it is a change in the internal structure of the secreted protein. This means that initially the protein is in the form of a monomer and only during the excretion does this monomer change by aggregation into nanofibers and further subsequent joining of different types of spidroins gives rise to fibers that can stretch to 135% of their original length without rupture and from which spiders legs spinning to conjure nets.

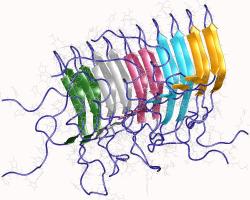

Amyloid prionového pentameru. Kredit: Wasmer, C., et al.: Protein Data Bank, CC BY 4.0

–

Now we come to the part where we talk about the middle ground. Even though it is known what spiders make their fibers, it is not possible to produce them industrially. But Zhang’s team may have found a solution. Instead of breeding spiders or classical synthetic chemistry, he used the abilities of bacteria. They, too, when properly spoken to them, begin to form spider protein. That is, unless anti-GMO activists burn a laboratory or officials, as a precautionary measure, prohibit playing with the genome by legislation. The truth is that bacteria long proteins do not like to form, and when it comes to a foreign molecule spidroin, especially. This led Zhang’s team to the idea of using an amyloid peptide to form fibers. It also aggregates similarly to spider spidroin and, under certain circumstances, forms stable nanofibrils.

Obtaining an amyloid peptide is not such a problem, many workplaces can do it, but the trick is that Zhang’s team manages to obtain amyloid recombinant peptides enhanced by modified amino acid sequences of spider fiber proteins. And this is the way to obtain fibers with particularly attractive properties. Much will soon be discussed about this new strategy for fiber production by fusing amyloid peptides with flexible spidroin linkers. Why?

In principle, the longer the protein molecule, the stronger and more resistant the fiber obtained from it. It is clear from recently published work that Zhang’s team manages to create sufficiently long hybrid molecules capable of aggregation and that these fibers can be wet-spun into macroscopic fibers. This is the first reason – the technological feasibility of obtaining fibers.

Polymeric amyloid fiber. (Credit: Jingyao Li)

–

The second is that their obtained macroscopic fibers have “gigapascal strength” – their tensile strength is truly admirable. The force required to break a fiber of a given diameter is greater than that of ordinary steel wire. Even the new fiber does not have to be ashamed of its toughness. To break, you need to expend more energy than the kevlar boasts. As a bead, the authors state that the strength and elasticity of their recombinant ones amyloid fibers are even higher than those reported for some natural spider silk fibers.

Fuzhong Zhang, team leader – a graduate of Peking University, professor of chemical engineering at Washington University in St. Petersburg. Louis.

–

Two important works were published on the topic of bacterial synthesis of polymeric materials in the course of one month. The latter is informed about the equally recognized magazine – Nature. And it is also knowledge from the workshop of Zhang’s team. This time their work concerns titanium protein. Due to the mentioned titanium, we could rename this study to: “Clothes and accessories made of muscle fibers”. The sequence for the production of titanium protein, which they then used to play with bacteria, the researchers borrowed from the calf muscle. Probably not to provoke the public too much, so from the rabbit. They modified the titin-forming sequence to suit their favorite Escherichia coli bacterium. A DNA fragment with the appropriate nucleotide sequence was inserted into its genome using a vector. Then only the intestinal bacteria gave them peace and favorite food.

Polymerized muscle protein titanium spun into a fiber should be useful in the healthcare, clothing industry, as well as in the production of protective equipment for the military and police. (Credit: Fuzhong Zhang Lab)

–

Bacteria according to an instruction smuggled into their genome formedand what they had – a high molecular weight mammalian muscle protein called titanium. It is possible considered a big step in microbiology, as microbes have managed to form a proteina molecule that is not only foreign, but from the I know spin into fibers quality similar to those spiders. Pfrom scientists NSO material suitable wherever high strength and flexibility are required. For example, shoelaces, belts, light bulletproof vests, and or only as firming part trainen fabrics. In the case of human titin, it will be a biocompatible material that does not cause allergic reactions and is suitable, for examplelad for sewing wounds. Titanium fibers, like the previous ones, are also stronger than silk, nylon and kevlar.

Probably the most important thing about the whole work is that we managed to create a technological platform that can be modified bacteria to themselves provided the opportunity folding smaller protein segments into ultra high molecular weight polymers. In this case about two megadaltons in size, which is 50 times iníce, than has their ordinary bacterial protein. Produced material can be for example spinningat and change in fibers approximately 10 microns in diameter or one tenth of the thickness of a humanyeah vlasu. The presented technique should gradually gain a wide application, the scope of which is difficult to imagine at the moment.

Literature

Jingyao Li, et al.: „Microbially Synthesized Polymeric Amyloid Fiber Promotes β-Nanocrystal Formation and Displays Gigapascal Tensile Strength“. ACS Nano 2021 , 15 , 7 , 11843–11853

Christopher H. Bowen, et al.: „Microbial production of megadalton titin yields fibers with advantageous mechanical properties“. Nature Communications 12, Article number: 5182 (2021)

Washington University McKelvey School of Engineering 2021

– .